Hightech for the cleaning of smallest particles

Megasonic technology

Introduction

Megasonic cleaning is a form of cleaning based on the use of high-frequency sound waves to clean surfaces. Although the term “megasonic” is not strictly defined scientifically, it is often used in connection with sound waves in the high frequency range of ultrasound. While “classic ultrasound” in cleaning applications tends to be in the range of 20kHz to 40kHz (i.e., 20,000 to 40,000 vibrations per second), megasonic cleaning typically uses significantly higher frequencies (usually from 400kHz upwards to several MHz). The technology is often used in industrial processes to thoroughly clean sensitive or complex components and remove very small particles (down to a few nanometers).

Megasonic cleaning

Functionality

In megasonic cleaning, high-frequency sound waves are conducted through a liquid (usually water or a solvent or cleaning agent). These sound waves create tiny bubbles in the liquid which collapse and produce an intensive cleaning effect. This process is called cavitation*.

*Cavitation: High-frequency sound waves cause small gas bubbles to form in the liquid. When these bubbles implode, they generate microscopic pressure waves that can remove dirt, oil, and deposits from surfaces.

Advantages of megasonic cleaning

- Thorough cleaning: The technology removes dirt even from hard-to-reach areas, such as tiny crevices or recesses.

- Non-abrasive: Since no mechanical friction is required, the material being cleaned remains undamaged.

- Effective on even the smallest contaminants: Ideal for cleaning the smallest particles, as required in the electronics or semiconductor industry, for example.

- More environmentally friendly: Cleaning is often carried out without aggressive chemicals, which reduces the impact on the environment.

Areas of application

- Semiconductors: Cleaning of wafers and photomasks in the semiconductor industry (most common application)

- Laboratory and research: For sonication and cleaning of various substrates and applications in the research sector.

- Industry: Removal of dirt and oily residues, e.g., from lenses (optics) or electronic components.

- Other: Cleaning or development support for a range of other scientific tasks, including in the food industry.

To summarize

Megasonic cleaning is an advanced and gentle method for efficiently cleaning sensitive and complex substrates.

Megasonics vs. Ultrasonics

Similarities and differences

The term “megasonic” primarily refers to higher frequency ranges or more intensive cleaning processes compared to conventional ultrasonic cleaners, although there are no uniform definitions here. The frequency range in the field of cleaning can be estimated at approx. 20kHz-40kHz for ultrasonic cleaners and approx. 400kHz-9MHz for megasound cleaners. The following chapter discusses further differences in more detail.

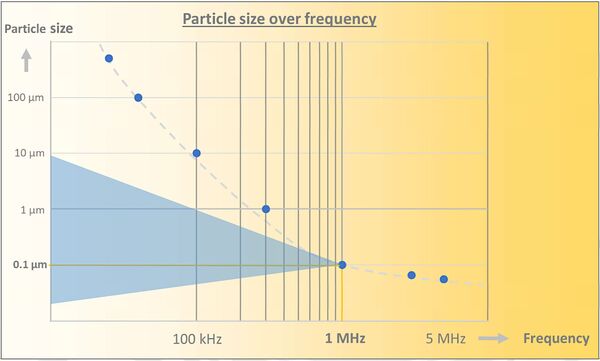

Both ultrasonic waves and megasonic waves are used for the vibrations of the piezo-ceramics in order to generate cavitation effects in the medium. These cavitation bubbles are larger in diameter with ultrasound, which also increases the intensity of the implosion. This is particularly helpful when cleaning coarser particles (several µm to several hundred µm), as the higher intensity comes into play here. However, this higher intensity can also result in damage to the substrate that is actually being cleaned. This is particularly the case with sensitive structures such as MEMS sensors or semiconductor wafers.

Cleaning examples

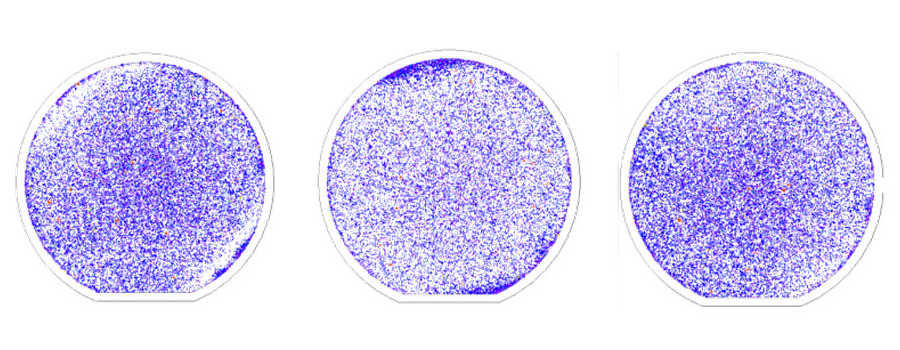

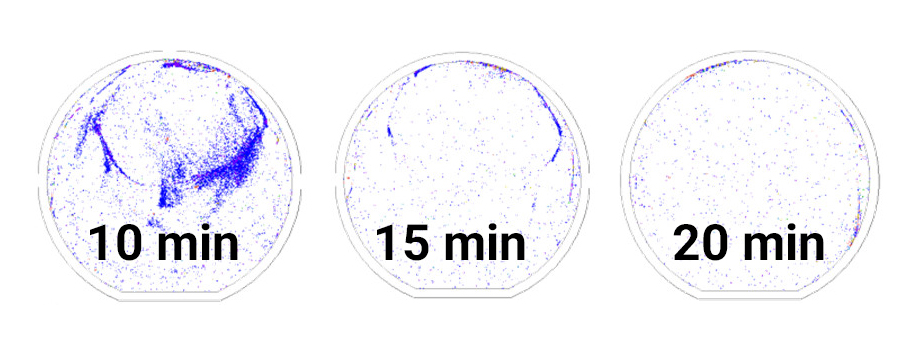

Example: Wafer cleaning

This cleaning example shows wafers with a high particle load that were cleaned in the bath at 1MHz / 500W / medium: DIW over various periods of time.

Topcon-measurements from 100nm

Source: provided by ims Chips Stuttgart, Germany

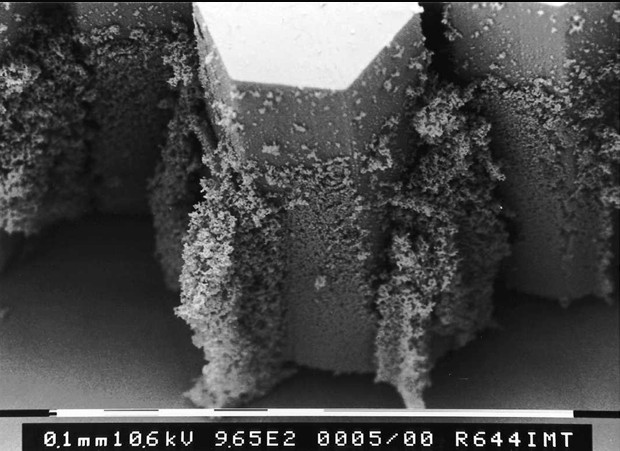

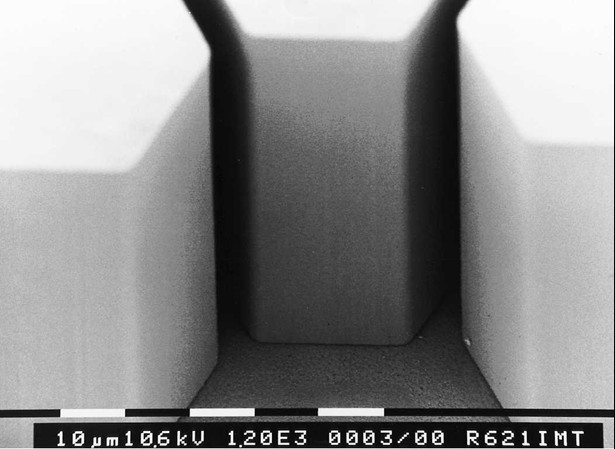

Example: Lithographic electroplating (LIGA)

This cleaning example shows a structure with a high aspect ratio, which was produced using the LIGA process (litho-galvanic) at KIT in Karlsruhe and optimized in collaboration with SONOSYS® with regard to the removal and permeability of cleaned particles in order to shorten the development time and increase the aspect ratio.

Source: provided by KIT (IMT) in Karlsruhe, Germany

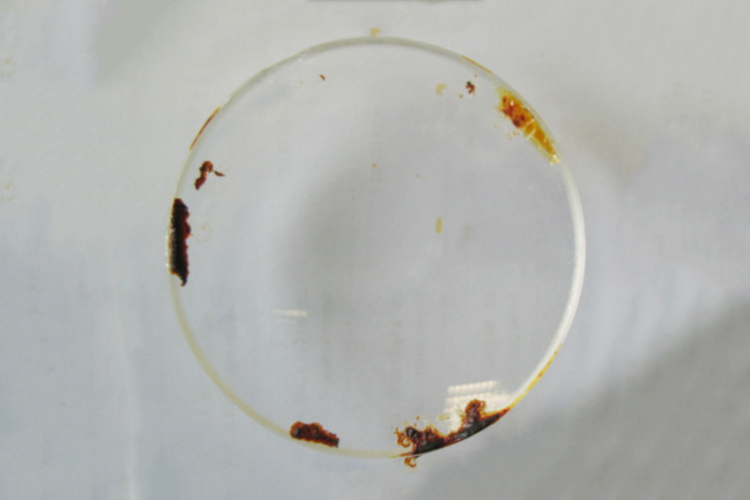

Example: Optics

This cleaning example shows an optical component before cleaning in the left-hand image. It clearly shows signs of heavy soiling. The optical component was then cleaned using a 600kHz nozzle from SONOSYS®. The success of the cleaning process can be seen in the right-hand image.

Quelle: mit freundlicher Bereitstellung von IPCM (?)

9 reasons for Megasonics

Avoid damages

Solution: Use higher frequencies

Benefits: No or significantly less damage, higher yield, cost savings

Remove smallest particles

Solution: Higher frequencies, process optimization

Benefits: Mega-sound applications enable effective cleaning with rates >98% at 1µm (PRE); higher yield

Optimize space requirements

Solution: Customized adaptations, modular design

Benefits: Integration options even when space is limited in the wet chamber

Customization

Solution: Customized solutions

Benefits: SONOSYS® offers solutions tailored to customer requirements

Homogeneous cleaning results

Solution: Long development history for the best possible homogeneity. Quality monitoring using our own cavitation sensor.

Benefits: Homogeneous cleaning results, objective quality monitoring

Consultations by experts

Solution: With over 30 years of experience in the field of mega sound, SONOSYS® is available as a competent partner.

Benefits: Avoidance of costly mistakes for customers, access to partner network, proven technology.

High product reliability

Solution: Robust design, high quality and reliability, and maintenance-free products

Benefits: Minimal or no downtime, no recurring maintenance costs

Effective use

Solution: indirect sound reinforcement, special coatings for the transducer

Benefits: can also be used in harsh environmental conditions, reliable industrial solution, low or no metal contamination

Partnership-based relationship

Solution: Highly flexible organization, ISO 9001 certified company, stable management, proven technology

Benefits: Long-term partnership, reliable solutions, low/no downtime, good product availability